from DN15 to DN200 - from PN16 (class 150) to PN630 (class 2500) - from -30°C to +120°C

Description

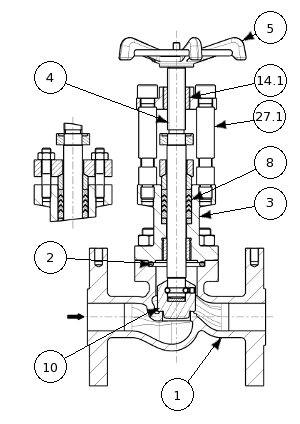

Globe valve with outside screw and yoke. The flanged body and the bolted bonnet are made of copper alloy (#CuSn). The stem and the throttling plug are made of nickel alloy (#Monel™). The plug is designed so as to avoid fire ignition while opening the valve. The integrated seat and a very neat lapping ensure bubble-tight shut-off.

Applications

This range of valves has been specially designed for gaseous oxygen service. These valves can also be installed behind a barrier, with or without gear box. They are extensively used in industry, especially in steel plants.

General features

- Body and bonnet in copper alloy (#CuSn)

- Stem and plug in nickel alloy (#Monel™)

- Outside screw and yoke

- Throttling plug

- Metallic body gasket (Copper)

- Packing gland made of PTFE for PN<PN100 and made of graphite for PN>=PN100

Alternatives

- Gear operated (depending on size and pressure rating)

- Extended stem and remote handwheel for installation behind a barrier

- Body and bonnet made of nickel alloy (Monel or Inconel depending on sizes and pressure ratings) in case of corrosive atmospheres

- For valves installed behind a barrier, body and bonnet made of stainless steel is available and the selection of butt welding ends offer an economic solution

- Threaded ends (BS or NPT) and socket welding ends on request

- … (see codification)

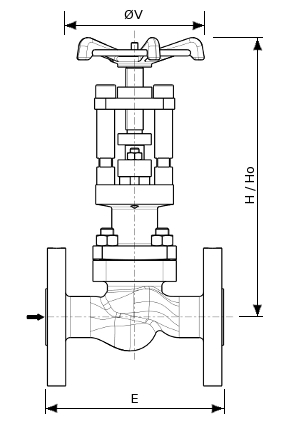

| Dimensions (mm) | Weight (W) in kg | ||||||

| DN1 | PN | E | H | Ho | ØV | W | |

| 15 | 20 (Class 150) | 160 | 228 | 242 | 125 | 8 | |

| 50 (Class 300) | 160 | 234 | 248 | 160 | 9 | ||

| 100 (Class 600) | 180 | 234 | 248 | 160 | 9 | ||

| 150 (Class 900) | 200 | 234 | 248 | 160 | 9,4 | ||

| 250 (Class 1500) | 200 | 234 | 248 | 160 | 9,4 | ||

| 420 (Class 2500) | 216 | 248 | 248 | 220 | 11 | ||

| 20 | 20 (Class 150) | 160 | 245 | 260 | 125 | 9,5 | |

| 50 (Class 300) | 210 | 276 | 290 | 220 | 10 | ||

| 100 (Class 600) | 210 | 276 | 290 | 220 | 10 | ||

| 150 (Class 900) | 230 | 276 | 290 | 220 | 10,5 | ||

| 250 (Class 1500) | 230 | 276 | 290 | 220 | 10,5 | ||

| 420 (Class 2500) | 228 | 395 | 395 | 220 | 30 | ||

| 25 | 20 (Class 150) | 160 | 245 | 260 | 125 | 10 | |

| 50 (Class 300) | 210 | 276 | 290 | 220 | 10,5 | ||

| 100 (Class 600) | 210 | 276 | 290 | 220 | 10,5 | ||

| 150 (Class 900) | 230 | 276 | 290 | 220 | 15 | ||

| 250 (Class 1500) | 230 | 276 | 290 | 220 | 15 | ||

| 420 (Class 2500) | 254 | 415 | 415 | 300 | 30 | ||

| 40 | 20 (Class 150) | 240 | 458 | 480 | 300 | 32 | |

| 50 (Class 300) | 240 | 458 | 480 | 300 | 35 | ||

| 100 (Class 600) | 260 | 458 | 480 | 400 | 36 | ||

| 150 (Class 900) | 323 | 482 | 482 | 220 | 95 | ||

| 250 (Class 1500) | 323 | 520 | 520 | 315 | 111 | ||

| 420 (Class 2500) | 350 | 520 | 520 | 400 | 120 | ||

| 50 | 20 (Class 150) | 185 | 365 | 388 | 220 | 17,5 | |

| 50 (Class 300) | 185 | 365 | 388 | 220 | 17,5 | ||

| 100 (Class 600) | 185 | 495 | 495 | 160 | 52 | ||

| 150 (Class 900) | 366 | 568 | 568 | 220 | 104 | ||

| 250 (Class 1500) | 366 | 606 | 606 | 315 | 127 | ||

| 420 (Class 2500) | 436 | 606 | 606 | 400 | 137 | ||

| 80 | 20 (Class 150) | 310 | 514 | 546 | 300 | 50 | |

| 50 (Class 300) | 337 | 631 | 631 | 220 | 91 | ||

| 100 (Class 600) | 337 | 631 | 631 | 220 | 96 | ||

| 100 | 20 (Class 150) | 350 | 530 | 570 | 300 | 80 | |

| 50 (Class 300) | 368 | 658 | 658 | 220 | 105 | ||

| 100 (Class 600) | 394 | 663 | 663 | 315 | 120 | ||

| 150 | 20 (Class 150) | 480 | 615 | 668 | 400 | 125 | |

| 50 (Class 300) | 508 | 774 | 774 | 315 | 146 | ||

| 200 | 20 (Class 150) | 600 | 980 | 980 | 500 | 350 | |

| 50 (Class 300) | 628 | 1000 | 1000 | 500 | 372 | ||

| With gear box by default | |||||||

| Standard materials | |||||

| Rep | Designation | Standard materials | |||

| (DN<DN50 or PN>PN100) | (DN>=DN50 & PN<=PN100) | ||||

| NF EN 1982 | Monel 400™ | NF EN 1982 | Inconel 625™ | ||

| 1 | Body | CuSn12-C CC483K | UNS N04400 | CuSn11Pb2-C CC482K | A494 GR CW6MC |

| B505 C90700 | NiCu30FeMn | B584 C92500 | NiCr22Mo9Nb | ||

| 2 | Body gasket | Copper / spring energized (Helicoflex® Cu) | |||

| NF EN 1982 | Monel 400™ | ||||

| 3 | Bonnet | CuSn12-C CC483K | UNS N0440 | ||

| B505 C90700 | NiCu30FeMn | ||||

| Monel K500™ | |||||

| 4 | Stem | UNS N05500 | |||

| NiCu29Al3Mn | |||||

| 5 | Hanwheel | AS13 Y30 | |||

| (PN<PN100) | (PN>=PN100) | ||||

| 8 | Packing | Chevrons PTFE | Graphite | ||

| Teflon™ | |||||

| NiCu30FeMn | |||||

| 10 | Metal plug | Monel 400™ | |||

| B164-B564 | |||||

| EN 1982 | |||||

| 14.1 | Stem nut | CuAl10Fe5Ni5-C CC333G | |||

| B505 C95800 | |||||

| EN 10269 | |||||

| 15 | Body studs | X5CrNiMo17-12-2 1.4401 | |||

| A320 GrB8M | |||||

| EN 10269 | |||||

| 16 | Body stud nuts | X5CrNi18-10 1.4301 | |||

| A194 Gr8 | |||||

| EN 10088-3 | |||||

| 27.1 | Pillars | X2CrNi18-9 1.4307 | |||

| A182 F304L | |||||

| for nickel alloy construction | |||||

| 1 | 5 |

5 |

9 |

0 |

0 |

- | X |

. |

. |

- | 0 | . | . | - | DN | .. | PN | .. |

|---|

| 1 | 5 | 5 | 9 | 0 | 0 | - | X | . |

. |

- | 0 | . | . | - | DN | .. | PN | .. |

|---|

| Value | Plug material |

|---|---|

| 7 |

St. st. construction |

| 9 |

Copper alloy or nickel alloy construction |

| 1 | 5 | 5 | 9 | 0 | 0 | - | X | . |

. |

- | 0 | . |

. |

- | DN | .. | PN | .. |

|---|

| Value | End connections |

|---|---|

| 1 |

Threaded ends |

| 3 | Flanged |

| 4 | Butt welding ends |

| 5 | Socket welding ends |

| 1 | 5 |

5 |

9 |

0 | 0 |

- | X | . |

. |

- | 0 | . |

. |

- | DN | .. | PN | .. |

|---|

| Value | Pressure rating |

|---|---|

| 1 | PN16 & class 150 |

| 2 | PN25 |

| 3 | PN 40 & class 300 |

| 4 | PN 64 & class 400 |

| 5 | PN 100 & class 600 |

| 6 |

PN 160 & class 900 |

| 7 |

PN 250 & class 1500 |

| 8 |

PN 420 & class 2500 |

| 1 | 5 |

5 |

9 |

0 | 0 | - | X | . |

. |

- | 0 | . | . | - | DN | .. | PN | .. |

|---|

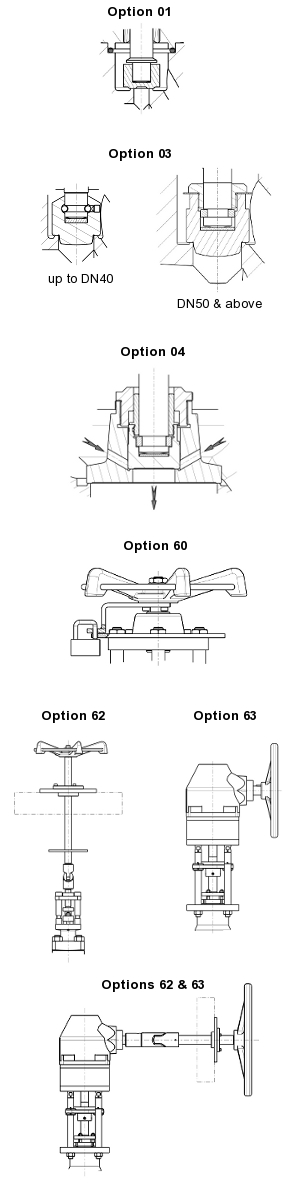

| Value | Option |

|---|---|

| A | Outside screw & yoke |

| G | Graphite packing |

| H | Metal body gasket |

| 1 | 5 |

5 |

9 |

0 | 0 | - | X | . |

. |

- | 0 | . |

. |

- | DN | .. | PN | .. |

|---|

| Value | Option |

|---|---|

| 01 | Screw down check valve |

| 03 | Throttling plug |

| 04 |

Internal by-pass |

| 17 | Hard faced seat |

| 30 | Limit switch open |

| 31 | Limit switch closed |

| 32 | Limit switch open and closed |

| 60 | Handwheel lock up device. |

| 62 |

Extended stem and remote

handwheel |

| 63 |

Bevel gear box |

| 65 | Electrical actuator |

| 67 | Spring return pneumatic actuator (air to close) |

| 68 | Spring return pneumatic actuator (air to open) |