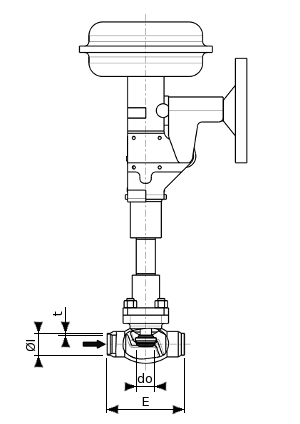

from DN15 to DN200 - from PN10 to PN760 - from -220°C to +200°C

Description

Stainless steel #304L globe valve equipped with a pneumatic or electric actuator. This valve is butt welding ended in its standard version and its bolted bonnet can be short (for ambient application) or extended (for cryogenic application or for coldbox installation). "In case of control application, the flow characteristic of the valve is ""equal %"" by default." Depending on your needs, we can supply the valve equipped with all of its accessories (solenoid valve, positioner, quick purge valve, position indicators, …)Applications

Designed for use on all air components gases in their standard version, these valves offer a wide range of options which allows the handling of a large variety of fluids. These valves are extensively used in every kind of industrial projects: air separation plants, petrochemical plants, dangerous products transportation, …General features

- In cryogenic service, the use of a stainless steel cryogenic extension (bonnet and stem) reduces the calorific conduction between the very low temperatured flowing medium and the packing. This ensures perfect tightness of packing in service conditions.

- The sturdy design, the high-quality of the selected materials and the high-performance components of these valves provide to them multi-purpose characteristics.

- These valves do not contain copper or copper alloy in contact with the atmosphere.

- A wide range of seat orifice diameters is available which enables an optimum flow coefficient Cv selection.

Alternatives

- Extension length upon demand

- Plug with PCTFE (Kel-F™) soft insert

- Flow characteristic upon demand for control valves

- Socket-welding ends or flanged ends

- Stainless steel #316L construction

- Construction without copper or copper alloy in contact with the flowing medium

- Fire safe construction

- Renewable seat / reduced trim

- … (see codification)

| CONTROL VALVES Cv TABLE | |||||||

| DN (standard PN) |

DN15 (PN100) |

DN20 (PN100) |

DN25 (PN100) |

DN32 (PN100) |

DN40 (PN100) |

DN50 (PN100) |

|

| Seat orifice | |||||||

| Ø4 | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 | |

| Ø6 | 1 | 1,1 | 1,1 | 1,1 | 1,1 | 1,1 | |

| Ø8 | 1,8 | 1,9 | 1,9 | 1,9 | 1,9 | 1,9 | |

| Ø10 | 2,7 | 2,9 | 2,9 | 2,9 | 2,9 | 2,9 | |

| Ø15 | 4,7 | 5,8 | 6,2 | 6,5 | 6,5 | 6,6 | |

| Ø20 | 8 | 10 | 11 | 11 | 12 | ||

| Ø25 | 13 | 16 | 17 | 18 | |||

| Ø28 | 21 | 22 | |||||

| Ø32 | 25 | 28 | |||||

| Ø40 | 33 | 44 | |||||

| Ø50 | 46 | ||||||

| Ø65 | |||||||

| Ø80 | |||||||

| Ø100 | |||||||

| Ø125 | |||||||

| Ø150 | |||||||

| Ø175 | |||||||

| Ø200 | |||||||

| CONTROL VALVES Cv TABLE | ||||||

| DN (standard PN) |

DN65 (PN68) |

DN80 (PN50) |

DN100 (PN50) |

DN150 (PN50) |

DN200 (PN50) |

|

| Seat orifice | ||||||

| Ø4 | 0,5 | 0,5 | 0,5 | 0,5 | 0,5 | |

| Ø6 | 1,1 | 1,1 | 1,1 | 1,1 | 1,1 | |

| Ø8 | 1,9 | 1,9 | 1,9 | 1,9 | 1,9 | |

| Ø10 | 2,9 | 2,9 | 2,9 | 2,9 | 2,9 | |

| Ø15 | 6,6 | 6,6 | 6,6 | 6,6 | 6,6 | |

| Ø20 | 12 | 12 | 12 | 12 | 12 | |

| Ø25 | 18 | 18 | 18 | 18 | 18 | |

| Ø28 | 23 | 23 | 23 | 23 | 23 | |

| Ø32 | 29 | 30 | 30 | 30 | 30 | |

| Ø40 | 44 | 46 | 46 | 47 | 47 | |

| Ø50 | 63 | 68 | 71 | 73 | 73 | |

| Ø65 | 88 | 95 | 114 | 122 | 123 | |

| Ø80 | 110 | 158 | 181 | 186 | ||

| Ø100 | 170 | 268 | 285 | |||

| Ø125 | 350 | 428 | ||||

| Ø150 | 298 | 576 | ||||

| Ø175 | 714 | |||||

| Ø200 | 831 | |||||

Dimensions vary a lot depending on the applications of the valves (cryogenic service, coldbox installation, vacuum insulation, pneumatic actuator, electric actuator, …) as well as on the service conditions (size of the actuator itself). Please contact us for further dimensional details.

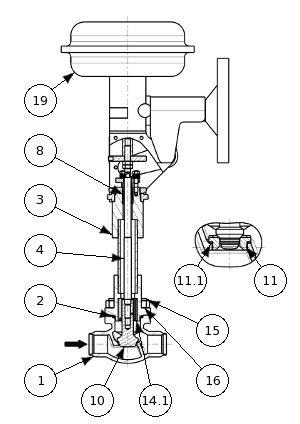

| Standard Materials | ||||||

| Rep | Designation | Standard Materials | ||||

| DN<=DN25 | DN25| DN>=DN150 |

| ||||

| EN 10222-5 | EN 10222-5 | EN 10213-4 | EN 10213-4 | EN 10213-4 | ||

| 1 | Body | X2CrNi18-9 1.4307 | X2CrNiMo17-12-2 1.4404 | GX2CrNi19-11 1.4309 | GX2CrNiMo19-11-2 1.4409 | GX2CrNiMo19-11-2 1.4409 |

| A182 F304L | A182 F316L | A351 CF3 | A351 CF3M | A351 CF3M | ||

| 2 | Body gasket | Graphite + 316L | ||||

| EN 10222-5 | EN 10222-5 | |||||

| 3 | Bonnet | X2CrNi18-9 1.4307 | X2CrNiMo17-12-2 1.4404 | |||

| A182 F304L | A182 F316L | |||||

| EN 10088-3 | ||||||

| 4 | Stem | X8CrNiS18-9 1.4305 | ||||

| AISI 303 | ||||||

| 8 | Packing | PTFE (Teflon™) | ||||

| EN 10088-3 | EN 10088-3 | |||||

| 10 | Plug | X8CrNiS18-9 1.4305 | X2CrNiMo17-12-2 1.4404 | |||

| AISI 303 | A182 F316L | |||||

| EN 10272 | ||||||

| 11 | Renewable seat | X2CrNi18-9 1.4307 + Stellite™ | ||||

| A182 F304L | ||||||

| 11.1 | Seat gasket | PCTFE (Kel-F™) | ||||

| NF EN 1982 | ||||||

| 14.1 | Screw | CuSn7Zn4Pb7-C CC493K | ||||

| B505.836 | ||||||

| EN 10269 | ||||||

| 15 | Stud | X5CrNiMo17-12-2 1.4401 | ||||

| A320 GrB8M | ||||||

| EN 10269 | ||||||

| 16 | Nut | X5CrNi18-10 1.4301 | ||||

| A194 Gr8 | ||||||

| 19 | Actuator | Electric or pneumatic | ||||

| 6 | 0 |

0 |

7 |

0 |

0 |

- | X |

. |

. |

- | 0 | . | . | - | DN | .. | PN | .. |

|---|

| 6 | 0 | 0 | 7 | 0 | 0 | - | X | . |

. |

- | 0 | . | . | - | DN | .. | PN | .. |

|---|

| Value | Valve type |

|---|---|

| 5 |

Short stem |

| 6 |

Cryogenic extension |

| 7 |

Angle valve |

| 8 |

Cryogenic extension for coldbox

installation |

| 9 |

Top entry |

| 6 | 0 | 0 | 7 | 0 | 0 | - | X | . |

. |

- | 0 | . |

. |

- | DN | .. | PN | .. |

|---|

| Value | End connections |

|---|---|

| 2 |

PCTFE disc |

| 6 |

Metal plug (st. st.) |

| 6 | 0 |

0 |

7 |

0 | 0 |

- | X | . |

. |

- | 0 | . |

. |

- | DN | .. | PN | .. |

|---|

| Value | Pressure rating |

|---|---|

| 1 | Threaded ends |

| 2 | Screwed ends |

| 3 | Flanged |

| 4 | Butt welding ends |

| 5 | Socket welding ends |

| 6 | 0 |

0 |

7 |

0 | 0 |

- | X | . |

. |

- | 0 | . |

. |

- | DN | .. | PN | .. |

|---|

| Value | Pressure rating |

|---|---|

| 1 | PN16 & class 150 |

| 2 | PN25 |

| 3 | PN 40 & class 300 |

| 4 | PN 64 & class 400 |

| 5 | PN 100 & class 600 |

| 6 | 0 |

0 |

7 |

0 | 0 | - | X | . |

. |

- | 0 | . | . | - | DN | .. | PN | .. |

|---|

| Value | Option |

|---|---|

| E |

ATEX CE Ex II 2G/D |

| G | Graphite packing |

| H | Metal body gasket |

| I |

Reinforced packing and drain

connections |

| J |

Reinforced packing |

| 6 | 0 |

0 |

7 |

0 | 0 | - | X | . |

. |

- | 0 | . |

. |

- | DN | .. | PN | .. |

|---|

| Value | Option |

|---|---|

| 10 | Reduced trim |

| 17 | Hard faced seat |

| 20 |

Without copper and copper alloys

in contact with the atmosphere |

| 21 |

Without copper and copper alloys |

| 22 |

Without copper and copper alloys

in contact with the flowing medium |

| 23 |

With stem bellow seal |

| 25 |

Special extended bonnet length |

| 30 | Limit switch open |

| 31 | Limit switch closed |

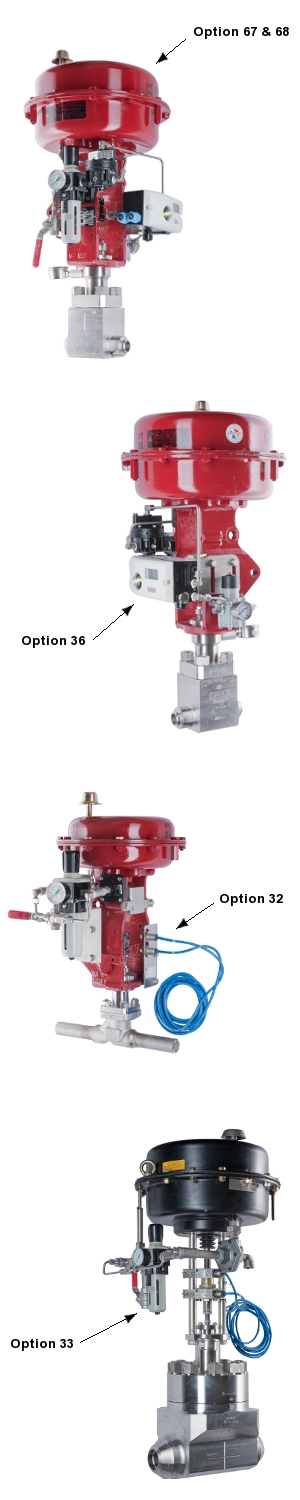

| 32 | Limit switch open and closed |

| 33 |

Air filter-reducer |

| 34 |

Solenoid valve |

| 35 |

Pneumatic positioner |

| 36 |

Electro-pneumatic positioner |

| 65 | Electrical actuator |

| 66 |

Double acting piston actuator |

| 67 | Spring return pneumatic actuator (air to close) |

| 68 | Spring return pneumatic actuator (air to open) |

Many alternatives are available, regarding actuators as well as the accessories that may equip these valves. The "know-how" of our technical staff and the engineering of the valves enable IRELAND to provide all-in control units.

Please do not hesitate to contact us for any further technical or commercial information.