from DN8 to DN200 - from PN10 to PN100 - from -220°C to +200°C

Description

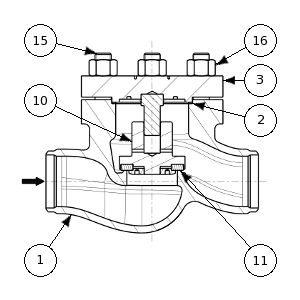

Stainless steel #304L lift-plug check valve with bolted bonnet and butt welding ends in its standard version. The bubble-tight shut-off is ensured through an integral seat and a renewable soft composition disc.Applications

Designed for use on all air components gases in its standard version, this check valve offers a wide range of options which allows the handling of a large variety of fluids. This check valve is extensively used in every kind of industrial projects: air separation plants, petrochemical plants, dangerous products transportation, ...General features

- the sturdy design, the high-quality of the selected materials and the high-performance components of this check valve provide to it multi-purpose characteristics.

- this check valve does not contain copper or copper alloy in contact with the atmosphere

Alternatives

- Lift plug closed by spring

- Metallic plug, throttling plug

- Socket-welding ends or flanged ends

- Stainless steel #316L construction

- Construction without copper or copper alloy in contact with the flowing medium

- Fire safe construction

- ... (see codification)

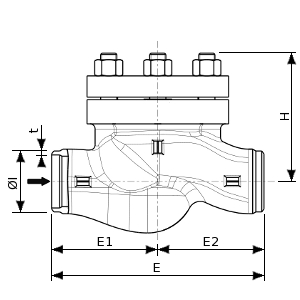

| Dimensions (mm) and | Weight (W) in kg | ||||||||

| DN1 | PN | Do | E | E1 | E2 | H | W | ||

| 8 | Up to 100 | 15 | 100 | 50 | 50 | 72 | 0,6 | ||

| 12 | Up to 100 | 15 | 100 | 50 | 50 | 72 | 0,6 | ||

| 15 | Up to 100 | 15 | 100 | 50 | 50 | 72 | 0,6 | ||

| 20 | Up to 100 | 25 | 130 | 50 | 80 | 80 | 1,6 | ||

| 25 | Up to 100 | 25 | 130 | 50 | 80 | 80 | 1,6 | ||

| 32 | Up to 100 | 160 | 80 | 80 | 89 | 2,5 | |||

| 40 | Up to 100 | 40 | 180 | 90 | 90 | 96 | 4,5 | ||

| 50 | Up to 100 | 50 | 210 | 105 | 105 | 118 | 8 | ||

| 65 | Up to 68 | 80 | 400 | 200 | 200 | 154 | 27 | ||

| 80 | Up to 50 | 80 | 310 | 155 | 155 | 154 | 25 | ||

| 100 | Up to 50 | 100 | 350 | 175 | 175 | 168 | 30 | ||

| 150 | Up to 50 | 150 | 480 | 240 | 240 | 238 | 75 | ||

| 200 | Up to 50 | 200 | 600 | 300 | 300 | 292 | 150 | ||

| forged body | |||||||||

| cast body | |||||||||

| Standard materials | ||||||

| Rep | Designation | Standard materials | ||||

| DN<=DN25 | DN25| DN>=DN150 |

| ||||

| EN 10222-5 | EN 10222-5 | EN 10213-4 | EN 10213-4 | EN 10213-4 | ||

| 1 | Body | X2CrNi18-9 1.4307 | X2CrNiMo17-12-2 1.4404 | GX2CrNi19-11 1.4309 | GX2CrNiMo19-11-2 1.4409 | GX2CrNiMo19-11-2 1.4409 |

| A182 F304L | A182 F316L | A351 CF3 | A351 CF3M | A351 CF3M | ||

| 2 | Body gasket | Graphite + 316L | ||||

| EN 10222-5 | EN 10222-5 | |||||

| 3 | Bonnet | X2CrNi18-9 1.4307 | X2CrNiMo17-12-2 1.4404 | |||

| A182 F304L | A182 F316L | |||||

| EN 10088-3 | EN 10088-3 | |||||

| 10 | Plug | X8CrNiS18-9 1.4305 | X2CrNiMo17-12-2 1.4404 | |||

| AISI 303 | A182 F316L | |||||

| 11 | Composition disc | PTFE (Teflon™) | ||||

| EN 10269 | ||||||

| 15 | Stud | X5CrNiMo17-12-2 1.4401 | ||||

| A320 GrB8M | ||||||

| EN 10269 | ||||||

| 16 | Nut | X5CrNi18-10 1.4301 | ||||

| A194 Gr8 | ||||||

| for #316L stainless steel construction | ||||||

| 2 | 6 | 0 | 7 | 0 | 0 | - | X | X | X | - | 00 | 00 | 00 | - | DN | .. | PN | .. |

|---|

| 2 | 6 | 0 | 7 | 0 | 0 | - | X | X | X | - | 00 | 00 | 00 | - | DN | .. | PN | .. |

|---|

| Value | Plug material |

|---|---|

| 1 | PTFE disc |

| 2 | PCTFE disc |

| 6 | Metal plug (st. st.) |

| 2 | 6 | 0 | 7 | 0 | 0 | - | X | X | X | - | 00 | 00 | 00 | - | DN | .. | PN | .. |

|---|

| Value | End connections |

|---|---|

| 3 | Flanged |

| 4 | Butt welding ends |

| 5 | Socket welding ends |

| 2 | 6 | 0 | 7 | 0 | 0 | - | X | X | X | - | 00 | 00 | 00 | - | DN | .. | PN | .. |

|---|

| Value | Pressure rating |

|---|---|

| 1 | PN16 & class 150 |

| 2 | PN25 |

| 3 | PN 40 & class 300 |

| 4 | PN 64 & class 400 |

| 5 | PN 100 & class 600 |

| 2 | 6 | 0 | 7 | 0 | 0 | - | X | X | X | - | 00 | 00 | 00 | - | DN | .. | PN | .. |

|---|

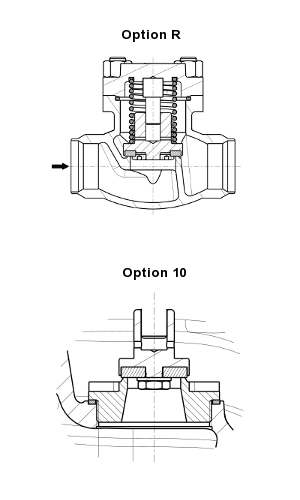

| Value | Option | E | ATEX CE Ex II 2G/D |

|---|---|

| H | Metal body gasket |

| R | With spring |

| 2 | 6 | 0 | 7 | 0 | 0 | - | X | X | X | - | 00 | 00 | 00 | - | DN | .. | PN | .. |

|---|

| Value | Option |

|---|---|

| 10 | Reduced trim |

| 17 | Hard faced seat |

| 20 | Without copper and copper alloys in contact with the atmosphere |

| 21 | Without copper and copper alloys |

| 22 | Without copper and copper alloys in contact with the flowing medium |